Cold storage manufacturers make cold rooms of different sizes, equipped with various features and components to meet the buyer's requirements. To give you an idea, industrial freezers can maintain temperatures in the range of -60°C to 15°C.

Cold room design is always a big concern and the team at Kendall Cold Chain System will explain the general steps in cold room design.

Step 1: Site selection and preparation

According to the nature of use, cold storage can be divided into distributed cold room, retailed cold room and productive cold room. Production cold rooms are built in areas where the supply of goods is concentrated, easily accessible and close to the market. Cold storage is best built in a cool place where there is no sunlight and frequent hot winds. Small cold stores are best built inside buildings. There should be good drainage around the cold store.

The water table should be low. It is preferable to have a mezzanine below and it is best to maintain good ventilation as dryness is important for cold storage. Before construction, the cold store should be set up with the appropriate three-phase electrical capacity according to the power of the machinery. If the cold store is to be water collapsed, water pipes should be laid and a cooling tower should be assembled at the same time.

Step 2: Confirm cold room capacity and temperature

The size of the cold room should be determined according to the maximum storage capacity for the year. The capacity is calculated based on the occupied volume of stored product, the rows, the space between the ceiling and piles and walls and the packaging gap. After determining the capacity of the cold room, we should determine the length and height of the cold room. The necessary ancillary buildings and facilities such as work rooms, packing rooms, tool rooms, loading and unloading rooms etc. should be considered in the cold storage design. The cold storage temperature should be designed according to the actual stored products and relative storage humidity to ensure food quality.

Cold Room Door

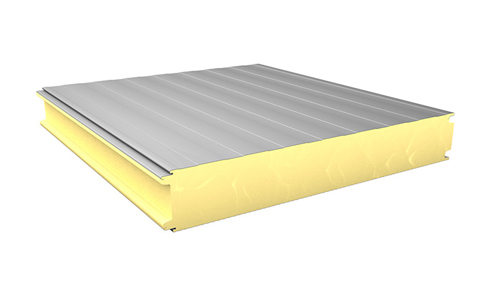

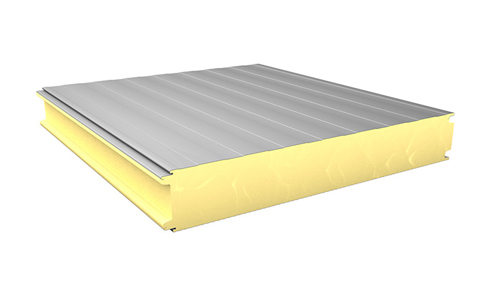

Step 3: Selection and installation of cold storage insulation materials

The choice of cold storage insulation materials should be adapted to the local conditions and measures. The material should not only have good insulation performance, but also be economical and practical. There are several types of cold storage insulation materials: one can be processed into a fixed shape and specification with a fixed length, width and thickness. Different cold room panels can be selected according to different assembly needs.

Cold Room Insulation Panel

High and medium temperature cold stores generally choose 10 cm thick panels. Low temperature and frozen cold rooms are available in 12cm or 15cm thick panels. Alternatively cold rooms can be made with sprayed polyurethane foam. We spray the material directly onto brick or concrete, which is shaped to provide moisture resistance and thermal insulation. Insulation materials include PU and PHB. PU is not heat resistant and provides good insulation but is costly. PHB is less insulating but less costly. Modern structures are being developed as assembled cold rooms where the moisture barrier and insulation are pre-fabricated and assembled on site. The advantages are ease of construction, speed, mobility and low cost.

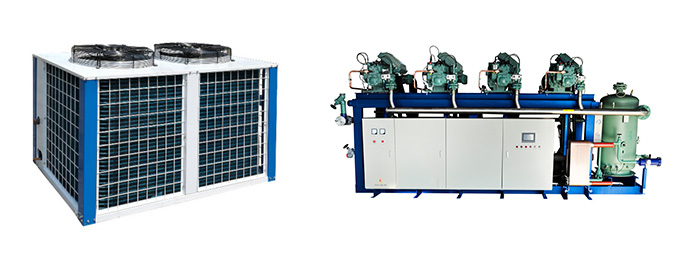

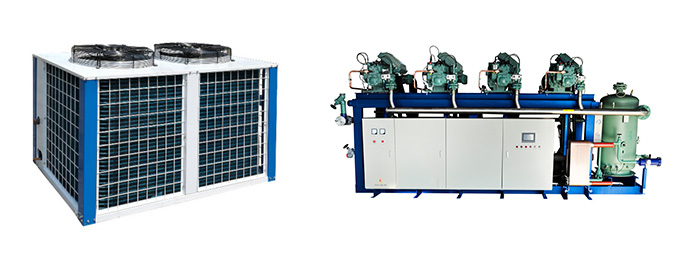

Step 4: Selecting a cold storage cooling system

The choice of cold storage refrigeration system mainly refers to the choice of refrigeration compressor and evaporator. Generally speaking, small cold storage choose fully enclosed compressor, because fully enclosed compressor power is small, the price is relatively cheap. Medium-sized cold storage generally choose semi-hermetic compressor. Large cold storage is the choice of semi-hermetic compressor. High temperature cold storage uses fan type evaporator, which is characterised by fast cooling speed, but easy to consume water. Medium and low temperature cold storage choose evaporation tube made of seamless steel pipe, which has good heat insulation and can store cold in time.

For further technical information talk with our specialist or visit our website https://www.kendallcool.com. We can help you to identify the best solution for your application.