Premium Cold Room Insulation Panel Solutions

Trusted Cold Room Panels Manufacturer for Reliable Insulation Performance

As a professional Cold Room Panels Manufacturer, Kendall Cold Chain System Co., Ltd. supplies high-performance Cold Room Insulation Panels designed to deliver superior thermal efficiency, structural strength, and long-lasting durability for cold storage facilities, industrial refrigerated warehouses, food processing plants, pharmaceutical storage, and commercial refrigeration projects.

Our Cold Room Insulation Panels are engineered to maintain stable internal temperatures, minimize energy loss, and support your cold chain requirements with consistent, optimized performance.

What Is a Cold Room Insulation Panel?

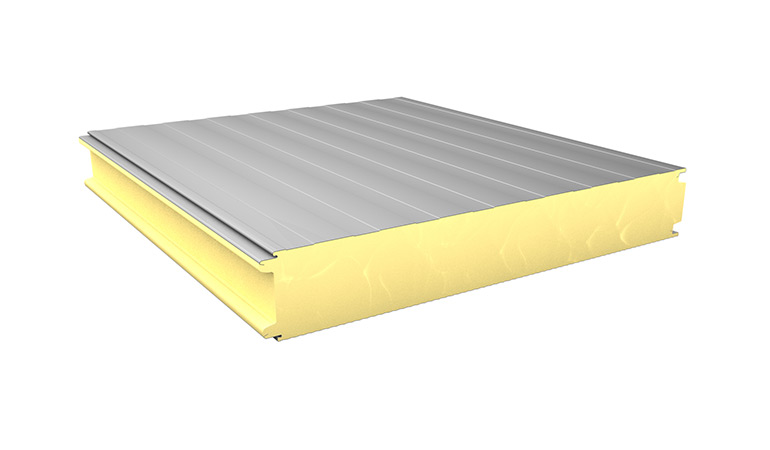

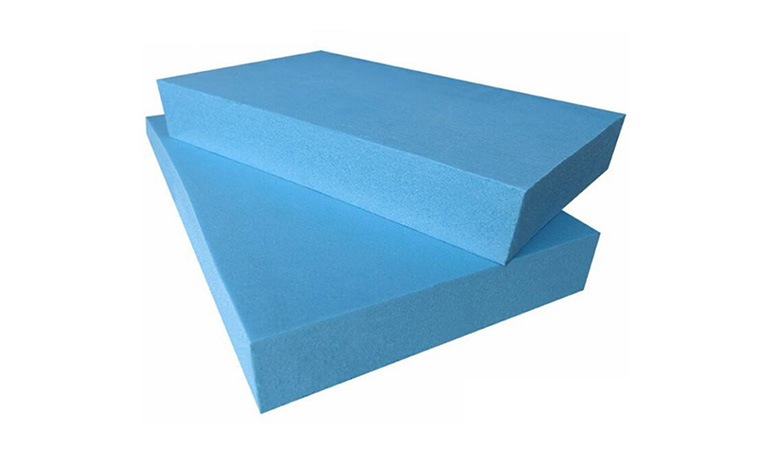

A Cold Room Insulation Panel is a core structural and thermal component used in the construction of cold rooms and refrigerated storage spaces. These panels combine high-grade insulation materials with protective facings to minimize heat transfer while maximizing strength and durability. Proper insulation is essential for reducing energy consumption and maintaining precise temperature control across chilled and frozen environments.

Our PUR Sandwich Panel uses light polyurethane as the inner core material for the cold storage panel. The purpose of using this material lies in the remarkable thermal insulation offered by the polyurethane. All the exterior of this panel is made up of SII, PVC color steel plate, and stainless-steel plate compartments, which forbids any temperature transmission during the logistics handling.

Key Features & Benefits

High Insulation Efficiency

Kendall Cold Room Insulation Panels deliver industry-leading thermal performance, helping maintain precise temperature zones while reducing energy consumption.

Moisture and Corrosion Resistance

Special surface coatings and moisture-resistant core materials protect against environmental factors, extending the lifespan of the cold room structure.

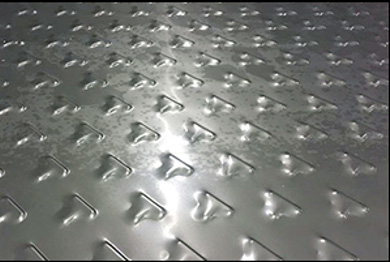

Structural Strength

Robust panel core and facing materials provide excellent load-bearing capacity and reliable performance under operational demands.

Custom Engineering Options

Whether you require non-standard panel lengths, specific thickness configurations, or pre-cut solutions for modular cold rooms, Kendall delivers tailored solutions to fit your project specifications.

Comprehensive After-Sales Support

As a trusted Cold Room Panels Manufacturer, we provide complete technical documentation, panel handling guidance, and responsive support throughout the project lifecycle.

Note:

Polyurethane rigid foam is the best insulation material for refrigeration equipment.

Why Choose Kendall Cold Room Insulation Panels?

Superior Thermal Performance

Our cold room insulation panels feature high-density core materials that provide excellent R-values and thermal resistance. This translates directly into:

Durable and Long-Lasting Construction

Kendall’s panels are manufactured using high-quality materials that resist moisture, impact, and corrosion. The result is a panel system that:

Withstands operational stresses

Maintains panel integrity over time

Requires minimal maintenance

Wide Range of Panel Thickness and Sizes

We offer a comprehensive selection of insulation panel sizes and thicknesses to meet diverse cold storage requirements, including:

Customization ensures the ideal balance between insulation performance and installation efficiency.

Enhanced Installation Efficiency

Our panels are precisely engineered for ease of installation with accurate dimensions, tight fitting joints, and complementary accessories. This reduces onsite labor, accelerates construction timelines, and ensures air-tight assemblies for optimal performance.

Typical Applications

Our Cold Room Insulation Panels are widely used in:

Cold Storage Warehouses – Chilled and frozen food storage

Supermarket and Retail Refrigeration – Walk-in cold rooms and freezers

Food Processing Facilities – Production and storage areas

Pharmaceutical Cold Chain – Temperature-sensitive medical storage

Industrial Refrigeration Projects – Chemical, biotech, and manufacturing environments

These panels serve a broad range of applications requiring stringent temperature control and energy-efficient performance.

Frequently Asked Questions

Q: What makes Kendall Cold Room Insulation Panels superior?

A: Our panels combine high-density insulation cores, moisture resistance, and robust facing materials to ensure long-term performance, energy efficiency, and reduced operational costs.

Q: Can insulation panels be customized?

A: Yes. We offer custom panel sizes, thicknesses, and facing options to align with specific cold room designs and performance targets.

Q: Are these panels suitable for both chilled and frozen storage?

A: Absolutely. Our Cold Room Insulation Panels are engineered to perform across a full range of cold chain temperature applications, from chilled environments to ultra-low freezing conditions.

Request a Quote or Technical Consultation

Interested in high-performance Cold Room Insulation Panels for your next cold storage or refrigeration project? Contact Kendall Cold Chain System today to:

Discuss your insulation requirements

Receive customized panel configurations

Obtain an accurate project quotation

Access engineering support and installation guidance

Partner with a trusted provider of engineered cold storage solutions.